Thermal cable is known as the most innovative electrical-thermal system in the world.

This product can be installed in safe and explosive environments under protective protocols.

Frost protection and temperature maintenance are the most common applications for electrical trace heating. This versatile and robust thermal technology is used in renewable energy systems, oil and gas processing, petrochemical/chemical processing, power generation, renewable energy systems, transportation, food and beverage production, environmental monitoring, and more.

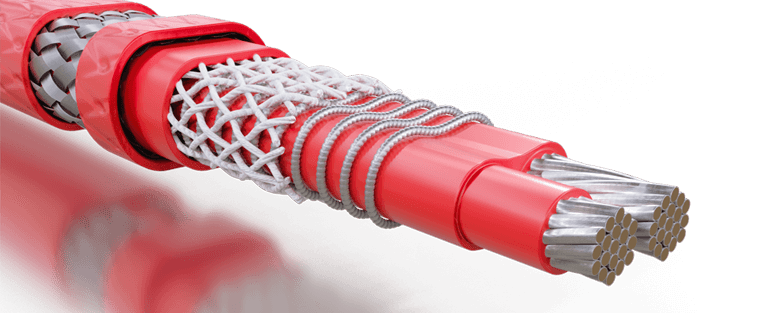

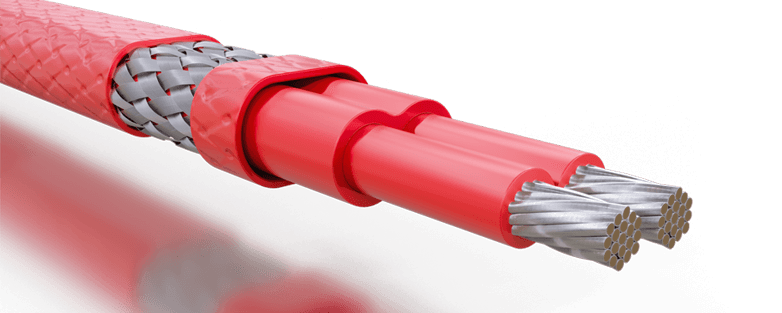

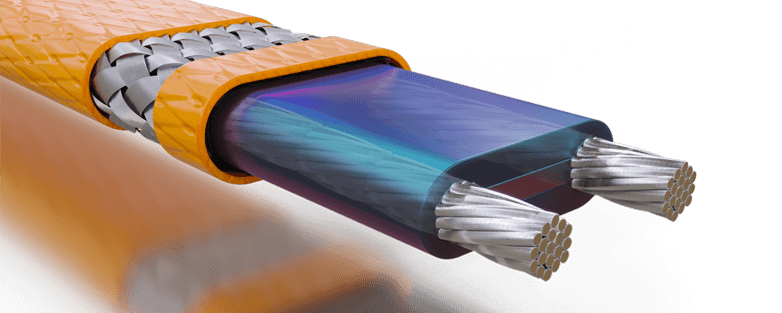

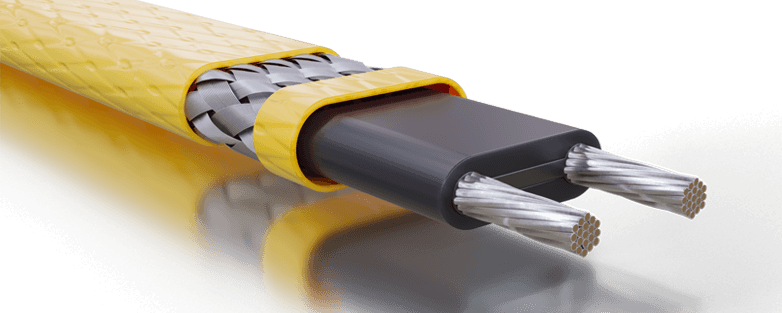

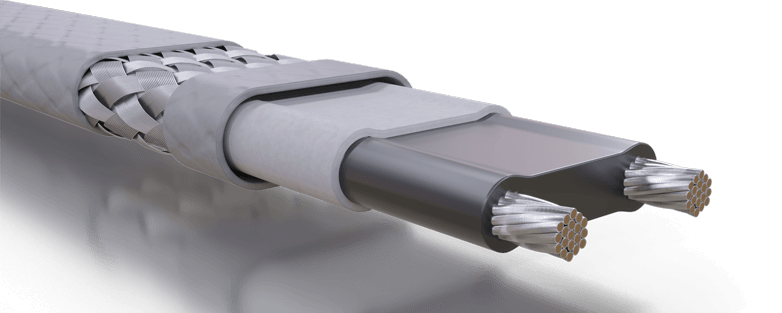

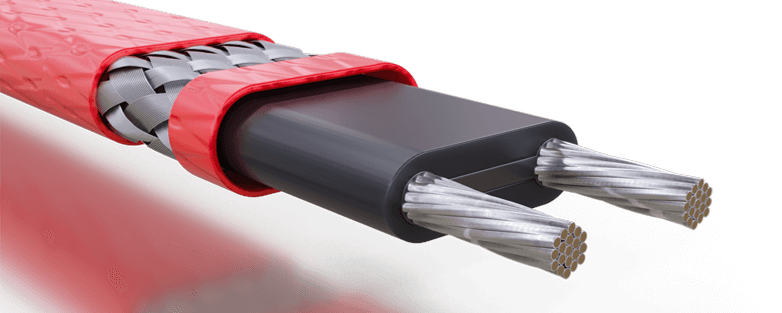

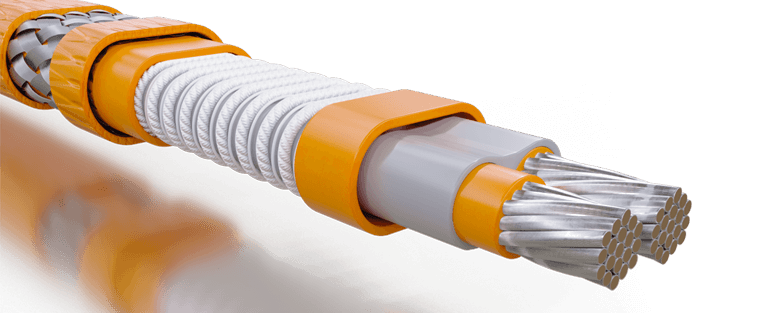

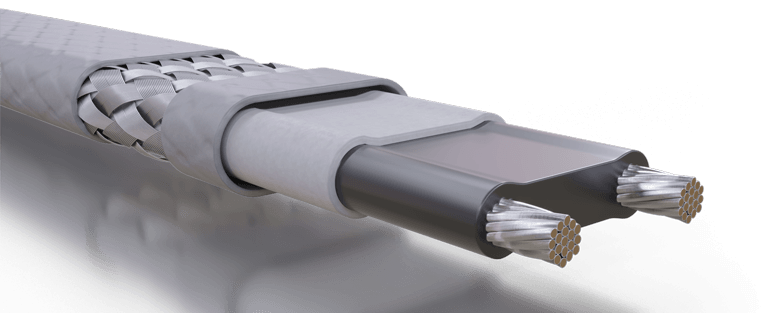

There are several components in the thermal cable that work in harmony to make it possible to maintain and regulate the temperature in even complex systems. One of the key components of the thermal cable is a semi-conducting and self-regulating element that provides the possibility of automatic adjustment of the output heat in response to the heat loss conditions in the entire circuit (when the ambient temperature decreases and causes heat loss in the equipment, the cable It responds by increasing its heat output. When the ambient temperature increases and the temperature in the equipment increases, the output of the cable decreases) that is installed along a pipe or other equipment surface. Once the thermal cables are securely fixed to the length of the pipe, they are both covered with layers of insulation and metal cladding to prevent heat loss.

the properties of the main element, this product has the ability to control the temperature according to the ambient temperature.

This product can meet the needs of industries with a wide range of production

Suitable for process cases where the fluid should not be in direct contact with the heating source.

The ability to produce heat up to +200 C°

Ease of installation and the ability to transfer heat to the farthest process station

The function of the thermal cable is to apply heat to an external surface, which compensates for the heat lost due to temperature changes in the surrounding environment. In cold or frosty conditions, heat cables help to stabilize the surface temperature of pipes or tanks through the heat cable to protect the flow of liquids inside and reduce the risk of equipment damage. Heat cables also maintain process temperatures for materials that can solidify or become too viscous in a system.