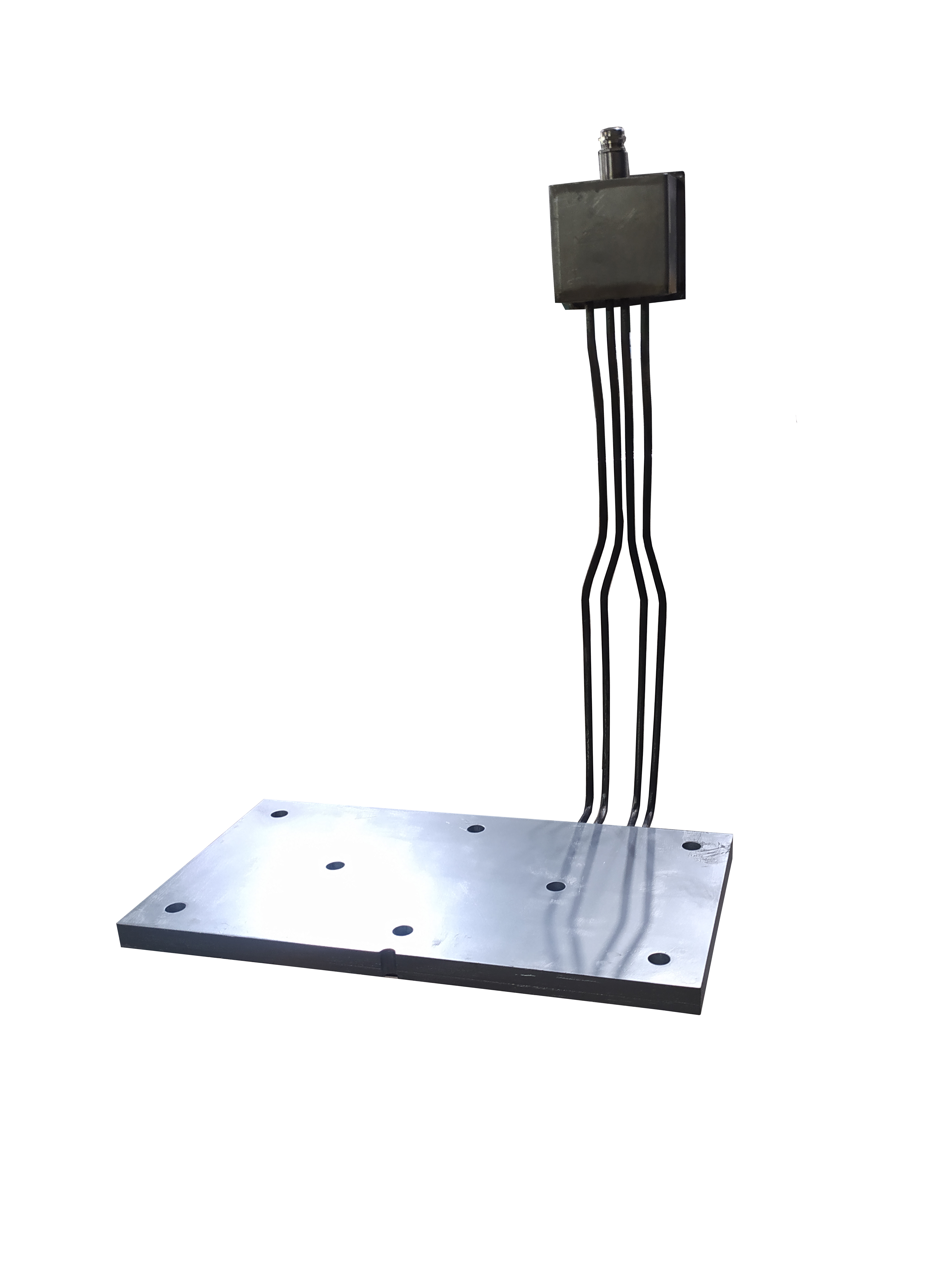

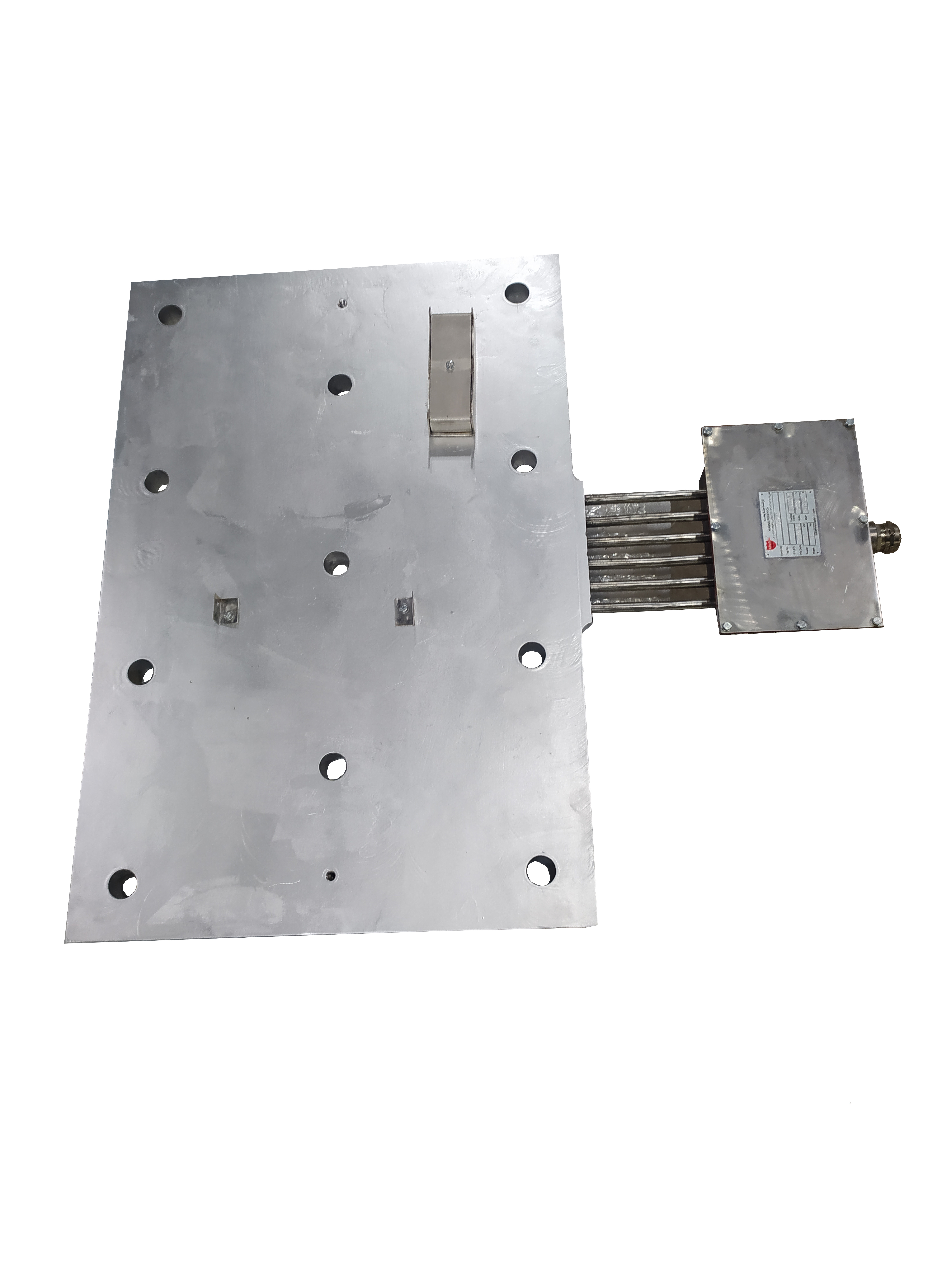

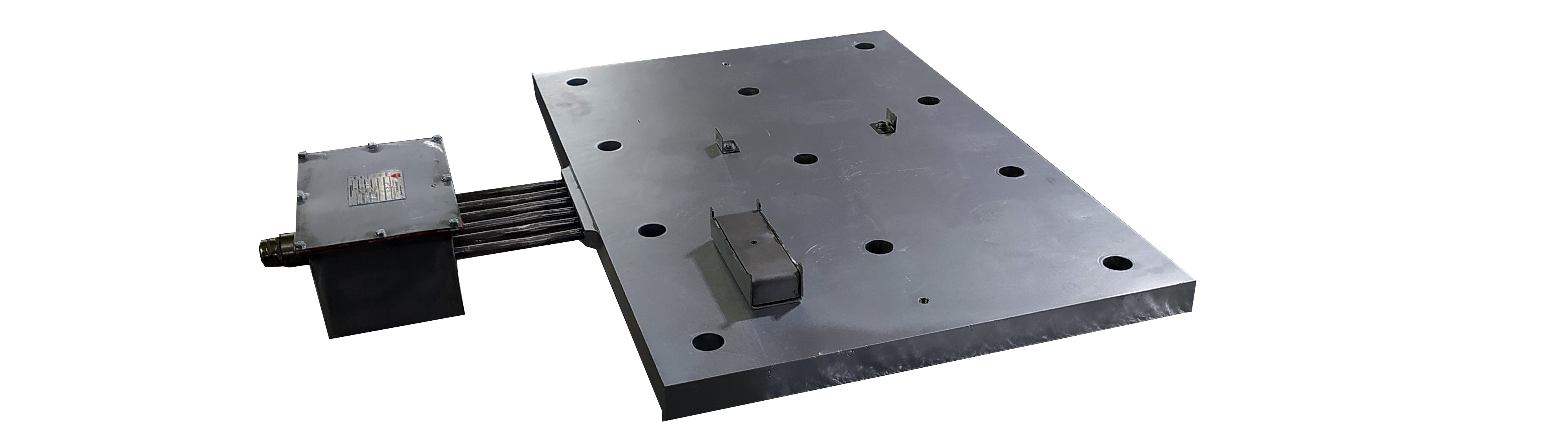

The cast-in heating plates and heating bands consist of one or several electrical resistances embedded in a block providing excellent thermal conductivity.

Electric plate heaters are first made by bending the rod element according to the dimensions of the plate, the constant surface temperature is obtained through proper shaping and then fixing in the mold is prepared for casting, gravity molding ensures excellent uniformity of the material. It guarantees and thus achieves excellent heat transfer. After casting, machining is done according to the plan.

Suitable for process cases where the fluid should not be in direct contact with the rod element.

The ability to produce blocks with different alloys (aluminum, brass and bronze)

The ability to produce heat up to 600+ degrees Celsius at all points of the block

High protection against corrosion, impact and industrial vibrations

The end-to-end control of the design and production chain allows us to deliver a product which suits your process perfectly